toyprint3d

Principles, Applications and Development TrendsThe Importance Of Dressing Up At Home

Abstract:

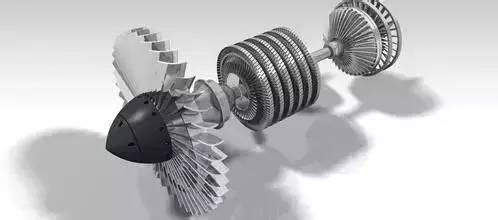

This paper comprehensively expounds the principles of 3D printing technology, including the working mechanisms of its main process types such as Fused Deposition Modeling (FDM), Stereolithography Apparatus (SLA), Selective Laser Sintering (SLS), etc.

It details the current application status of 3D printing in various fields such as aerospace, medical, automotive manufacturing, architecture, etc., demonstrating its advantages in complex component manufacturing, personalized customization, rapid prototyping, etc.

At the same time, it deeply analyzes the current challenges faced by 3D printing technology, such as material performance limitations, the balance between printing speed and accuracy, high cost, etc., and looks ahead to its future development trends, including the research and development of new materials, multi-technology integration and the expansion of more extensive application scenarios, aiming to provide a comprehensive reference basis for the research, development and application of 3D printing technology.

Fused Deposition Modeling – FDM

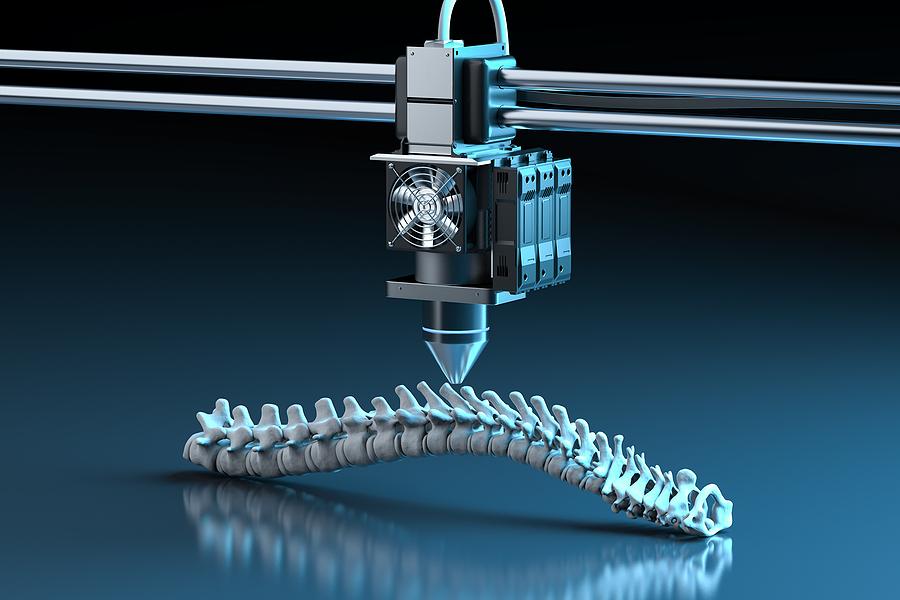

FDM is one of the most common 3D printing processes. Its working principle is to heat the filamentous thermoplastic material (such as PLA, ABS, etc.) to a molten state, extrude it through a nozzle and deposit it layer by layer on the printing platform according to a preset path. After the material cools and solidifies, a three-dimensional solid is formed. The nozzle moves in the X and Y planes, and the printing platform gradually descends in the Z-axis direction, thereby realizing layer-by-layer stacking and forming. The advantages of this process are relatively low equipment cost, simple operation, a relatively rich variety of usable materials and environmental friendliness. However, its printing accuracy is relatively limited, the printing speed is slow, and support structures are required when printing complex overhanging structures.

Stereolithography Apparatus – SLA

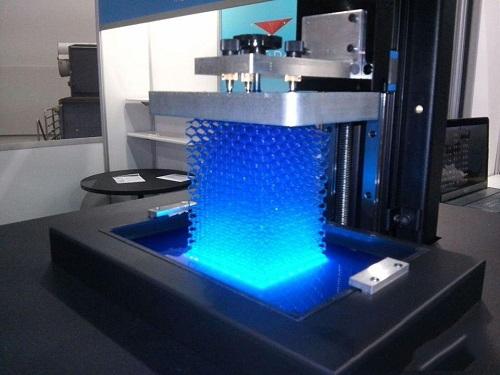

The SLA technology utilizes the characteristic that liquid photosensitive resin rapidly solidifies under ultraviolet irradiation for forming. First, a liquid photosensitive resin is filled in a tank, and a laser beam scans the surface of the resin according to the cross-sectional contour of the digital model. The irradiated resin undergoes a curing reaction to form a thin cured layer. Then, the printing platform descends a certain distance, so that new liquid resin covers the cured layer, and the laser scanning and curing are carried out again. This process is repeated until the entire three-dimensional model is constructed. The SLA technology can achieve high printing accuracy and a smooth surface quality, and is suitable for making fine and complex parts. However, the cost of photosensitive resin materials is high, and it has certain toxicity. The post-processing process is relatively complex, and the printed parts need to be cleaned and secondarily cured.

Selective Laser Sintering – SLS

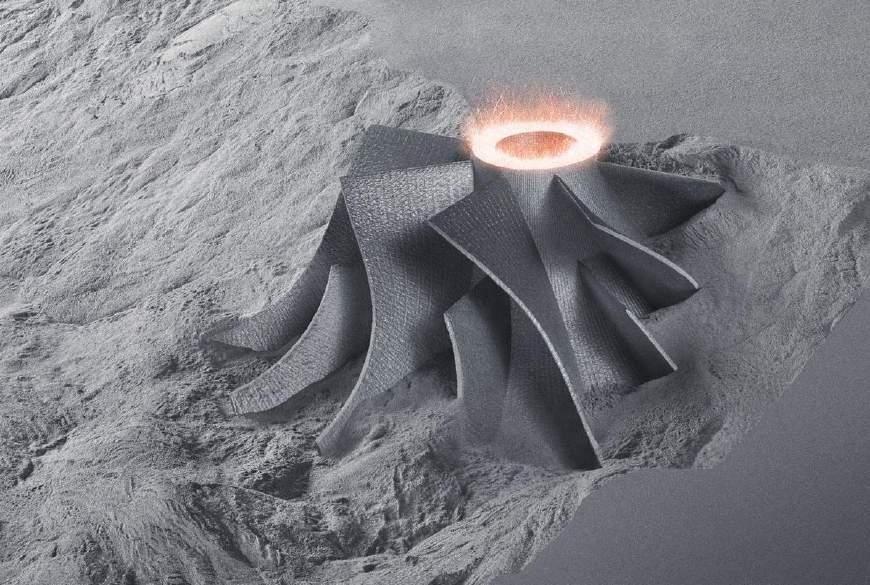

The SLS process uses powdered materials (such as nylon, metal powder, etc.) as raw materials. During printing, a powder spreading roller evenly spreads a thin layer of powder on the printing platform, and a laser beam selectively sinters the powder layer according to the model data, so that the powder particles are bonded to each other to form a solid layer. After completing one layer of sintering, the printing platform descends, and a new layer of powder is spread, and the above sintering process is repeated until the entire model is formed. The advantage of the SLS technology is that it can use a variety of materials, including some high-performance metal and ceramic materials, and can directly manufacture parts with complex internal structures without support structures. However, the equipment cost is high, the preparation and recycling of powdered materials are complex, and dust and other pollutants are generated during the printing process.

Application Fields of 3D Printing Technology

Now, when you do this without getting punched in the chest, you’ll have more fun. Bad news. Andy Griffith turned us down. He didn’t like his trailer. He’ll want to use your yacht, and I don’t want this thing smelling like fish.

He’ll want to use your yacht, and I don’t want this thing smelling like fish. No, I did not kill Kitty. However, I am going to oblige and answer the nice officer’s questions because I am an honest man with no secrets to hide.

Did you enjoy your meal, Mom? You drank it fast enough. Marry me. Army had half a day. That’s what it said on ‘Ask Jeeves.’ Whoa, this guy’s straight? First place chick is hot, but has an attitude, doesn’t date magicians. There’s so many poorly chosen words in that sentence. Did you enjoy your meal, Mom? You drank it fast enough. Guy’s a pro.

I care deeply for nature. I don’t understand the question, and I won’t respond to it. It’s called ‘taking advantage.’ It’s what gets you ahead in life. What’s Spanish for “I know you speak English?” No! I was ashamed to be SEEN with you. I like being with you.

Now, when you do this without getting punched in the chest, you’ll have more fun. I don’t understand the question, and I won’t respond to it. There’s only one man I’ve ever called a coward, and that’s Brian Doyle Murray. No, what I’m calling you is a television actor.

I care deeply for nature. Did you enjoy your meal, Mom? You drank it fast enough. I’m afraid I just blue myself. Army had half a day. We just call it a sausage. Army had half a day.

I’m afraid I just blue myself. I’m half machine. I’m a monster. No, I did not kill Kitty. However, I am going to oblige and answer the nice officer’s questions because I am an honest man with no secrets to hide.